Your shopping cart is empty!

Our Catalogue

- Abrasive/Grinding/Polish

- Arts/Crafts

- Airbrushes/Compressors

- Cutters/Blades

- Finishing/Cleaning Products

- Flexible Shafts

- Framing

- Glue Guns/Wood Burning Pens

- Mats

- Rotary Mini

- Rulers

- Scissors

- Wood Turning Chisels/Lathes

- Batteries

- Blow Torches

- Clamps/Jigs

- Biscuits

- Cabinet Jigs/Instal Tools

- Clamps

- Band Strap Cord / Frame Clamp

- Bar Clamps

- C/G-Clamps

- Clamp Storage

- Corner Mitre / Angle Clamps

- Edging Clamps

- F-Clamps

- Guide Rail Clamps

- Lever Clamps

- Parallel Clamps / Revo

- Pipe Clamps

- Quick / Hand Clamps

- Sash Clamps

- Sets

- Spare Parts

- Special / Other Clamps

- Spring Clamps

- T-Tracks Face Pocket Hole

- Toggle / Bench Dog Clamps

- Dominoes

- Doweling

- Drilling Jigs

- Guides/Supports/Accessories

- Lock Mortising

- Magnets

- Nibblers/Shears

- Pocket Hole/Decking

- Router Jigs

- Sawing Jigs

- Spare Parts

- Square Chisel Mortiser

- Vices

- Workbench/Router Table

- Cutting/Sawing

- Drilling

- Fan Merchandise

- Hand Tools

- Chisels

- Edge Trimmers

- Electric Cable Joints/Clamps

- Files

- Glass Cutters

- Glue Applicators

- Grease Guns/Accessories

- Hacksaws

- Hammers/Axes

- Hand Saws

- Hand Stapler/Riviter/Tape Tool

- Hand Taper Reamers

- Impact Sockets

- Magnifiers

- Meter Sealing Tools

- Other Hand Tools

- Pipe Cutters/Deburring Tools

- Pliers

- Bent Nose Pliers

- Bolt Cutters

- Chain Lock Grip Pliers

- Circlip Pliers

- Combination / Fencing Pliers

- Diagonal/Side Cutters

- End Nippers

- Eyelet Pliers/Grommet Set Tool

- Flat Nose Pliers

- Lock Grip/Vice Grip Pliers

- Long Nose Pliers

- Revolving Punch Pliers

- Round Nose Pliers

- Sets

- Sheet Metal Pliers

- Tweezers

- Water Pump Pliers

- Wire Stripper

- Punches

- Scroll/Fret Saw Frame

- Snips/Shears

- Sockets

- Tool Belts/Pouches

- Tool Boxes/Trolleys/Kits

- Wood Plane

- Wrenches/Spanners

- Measuring/Marking

- Bore Gauges

- Caliper/Thickness Gauges

- Calipers

- Depth Gauges

- Gauge Block Sets

- Gauges

- Hardness Testers

- Height Gauges

- Indicators

- Laser Dist Meter/Range Finder

- Levels

- Line

- Marking

- Measuring Tool Sets

- Metal Detectors

- Micrometer

- Microscopes

- Pens/Pencils/Note Books

- Positioned Gauges

- Protractors/Squares

- Roughness Testers

- Rulers

- Scales

- Scribers/Penknife

- Specialised meters

- Straight Edges

- Tape Measures

- Merchandising

- Outdoors/Lifestyle

- Packaging

- Pneumatics

- Air Treatment

- Compressor Spares

- General

- Hose Fittings

- Power Tools

- Pressure Gauges

- Prevost System

- Pu Fittings

- Reels/Pipe/Hose/Tubing

- Spray Finishing

- Power Tools

- Cordless

- Electric

- Festool Spare Parts

- Router Bits

- Architectural Bits

- Bearings/Bushings

- Bull Nose

- Dish Carving

- Domino Cutters

- Door Making Bits

- Fluting/Beading

- Jointing Bits

- Louvre/Shutter Bits

- Plunge Cutting Grooving Bits

- Profiles

- Pulls/Handles

- Rabbeting Bits

- Reducing Sleeves/Collets

- Sets

- Slotting Bits

- Spare Parts

- Special Bits

- Spindle Cutters

- Straight Bits

- Trimming Bits

- Turn Over Knives

- Safety

- Screwing/Fastening/Fixing

- Bonded Anchors

- Cable Ties

- Direct/Manual Fastening System

- Facade Insulation Fixings

- Fasteners

- Foams/Sealants/Adhesives

- Lightweight Fixings

- Mechanical Anchors

- Passive Fire Protection System

- Roofing Insulation Fixings

- Screwdriving Systems

- Sharpening

- Specialist Aerosols

- Transport

- Unassigned

- Unknown

- Warranty

Brands

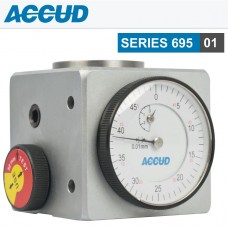

ZERO SETTER 0.0010MM ACC. MAGNETIC BASE

Price: R6,586.45

Ex Tax: R5,727.35

Ex Tax: R5,727.35

Qty:

- OR -

Add to Wish List

Add to Compare

Add to Compare

Zero Setter 50mm ±10µm Accuracy

SERIES 695

SERIES 695

A Dial Zero Setter 50mm with Magnetic Base is a precision tool used in machiningand milling operations to accurately set tool heights and measure workpiece positioningrelative to the machine's spindle or table. This tool, often referred to as a ZeroSetter, is essential for ensuring that cutting tools are precisely positioned, whichimproves accuracy and repeatability in machining tasks.

Benefits:

- Accurate Tool Height Setting: The dial zero setter ensuresthat cutting tools are accurately positioned, which is crucial for precisionmachining and maintaining consistent part dimensions.

- Time-Saving: It reduces the time needed for tool setupand allows for quick adjustments, enhancing productivity.

- Versatile: Useful in various applications, such as settingup CNC machines, milling machines, and lathes, for tasks requiring precise measurements.

A Dial Zero Setter with a magnetic base is an invaluable tool for machinistswho need reliable and repeatable tool height measurements, especially in precision-focusedmachining tasks. The magnetic base enhances its stability and ease of use, makingit a popular choice in machine shops.

Key Features:

- Dial Indicator: The zero setter includes a dial indicator with a large, easy-to-read dial face, usually with a measurement range of 50mm (or 2 inches) and ±10µm accuracy. The dial provides highly precise readings, with graduations as fine as 0.01mm, enabling operators to achieve accurate tool height settings.

- Magnetic Base: The tool is equipped with a magnetic base, allowing it to be securely attached to the machine table or other ferrous surfaces. This base stabilizes the zero setter during use, ensuring accurate and consistent measurements.

- Zero Position Setting: The dial indicator can be set to a zero position, which acts as a reference point for measuring tool height or depth. By zeroing the indicator, machinists can consistently return to the same position, reducing setup time and improving accuracy.

- Spring-Loaded Contact Surface: The zero setter has a spring-loaded contact surface that compresses when the tool touches the workpiece or machine spindle. This compression allows for a controlled and repeatable measurement, minimizing the risk of damaging delicate tools or work surfaces.

Technical Specifications

Tags:

Zero Setter